About

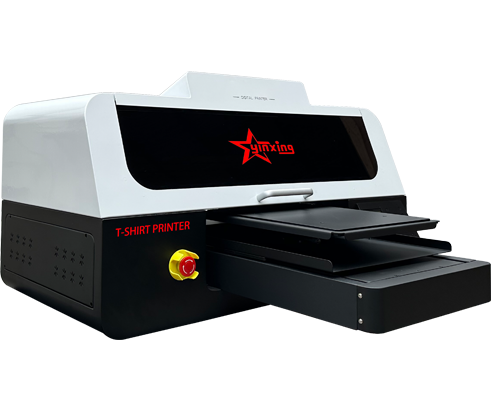

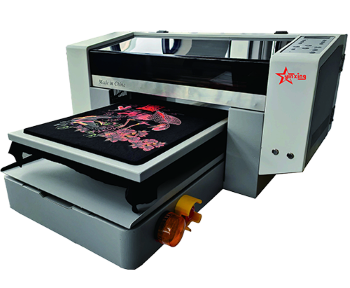

DTG Direct to Garment Printer

A Direct-to-Garment (DTG) printer is a digital printing machine specifically designed for printing detailed, full-color designs directly onto textiles, most commonly T-shirts and other clothing items. The process involves applying water-based inks directly onto the fabric, allowing for vibrant and detailed designs to be printed quickly and efficiently.

It is perfect for small businesses or artists looking to create custom-designed T-shirts, hoodies, and other garments.

Advantage of DTG Printing

High-Resolution Prints

Can produce complex and intricate designs with a wide range of vibrant colors and fine details. This makes them ideal for printing high-quality images, logos, or artwork directly onto fabric.

Cost-effective

0.3~0.4$ printing cost/A4 size print (for ink)

Long-lasting

The ink goes deep into the fabric fibers, creating a bond that resists fading, cracking, and peeling. The combination of high-quality water-based inks, pre-treatment, and heat curing ensures that the design stays vibrant and durable even after multiple washes

Breathable and Soft

DTG printers use water-based inks that are absorbed into the fabric fibers, creating soft, breathable prints. This results in a comfortable, long-lasting design that doesn’t crack or peel over time.

Ideal for Print on Demand

Ideal for companies that operate in print-on-demand markets, where orders are printed and shipped as they come in.

Eco-friendly

Since DTG printing doesn’t require chemical-heavy processes like screen printing, it is considered more environmentally friendly. It also uses water-based, non-toxic inks and generates less waste.